Wetting and dispersing additive for aqueous coatings. Suitable for resin-containing and resin-free pigment concentrates. For organic and inorganic pigments.

ข้อมูลผลิตภัณฑ์

ส่วนประกอบ:

Aqueous solution of copolymers containing highly pigment-affinity groups (EO, PO block copolymers).

คุณสมบัติทั่วไป:

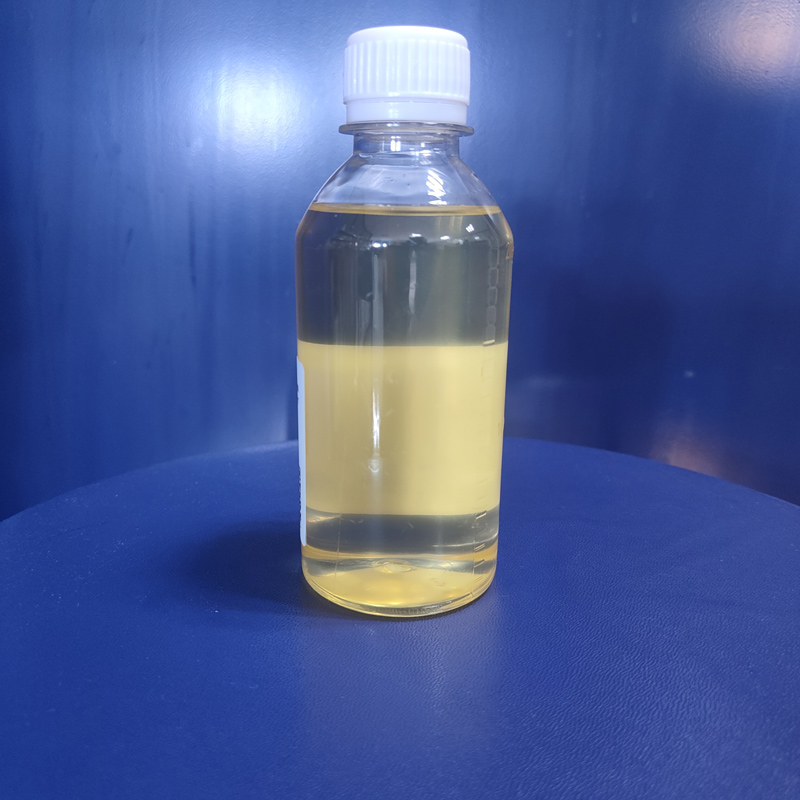

ลักษณะ: transparent liquid

Active content: 50%

กระสาย: น้ำ

ค่า PH: 6

*.ค่าที่ระบุในเอกสารข้อมูลนี้อธิบายคุณสมบัติทั่วไปและไม่ถือเป็นขีดจํากัดข้อมูลจําเพาะ.

โปรแกรม ประยุกต์

คุณสมบัติพิเศษและประโยชน์:

- Good coloring power and good viscosity reducing effect

- Good storage stability of colorant paste

- good water resistance

- No solvent

- Contains no ethoxyalkylphenol

การใช้งานที่แนะนํา

- Pigment concentrates are used in production

- Car paint (putty and primer)

- Industrial paint

- Flexo and gravure printing inks

- Inkjet inks

- Pesticide

Note: This instruction manual is for reference only and does not have any guarantee properties. Please test its applicability in advance.

จํานวนเงินเพิ่มเติม

Recommended Levels

Recommended addition amount:

Inorganic pigments: 5%-30%

Organic pigments: 20%-70%

Carbon black: 40%-120%

Recommended addition amount: 0.5%-2.0%

*. The above data are empirical dosages, และปริมาณที่เหมาะสมจะต้องถูกกําหนดผ่านการทดสอบหลายชุด.

คําแนะนําสําหรับการใช้งาน

Incorporation and Processing Instructions

To achieve the best performance, the additives should be added to the grind first, followed by the pigment. Premix the resin and solvent components of the grind, then slowly add the additives while stirring. Do not add the pigment until the additives are well mixed. The information herein is based on our present knowledge and experience. The information merely describes the properties of our products but no guarantee of properties in the legal sense shall be implied. เราแนะนําให้ทดสอบผลิตภัณฑ์ของเราว่าเหมาะสมกับวัตถุประสงค์ที่คุณคาดการณ์ไว้ก่อนใช้งาน. ไม่มีการรับประกันใดๆ,ไม่ว่าโดยชัดแจ้งหรือโดยนัย, รวมถึงการรับประกันความสามารถในการขายหรือความเหมาะสมสําหรับวัตถุประสงค์เฉพาะ, จัดทําขึ้นเกี่ยวกับผลิตภัณฑ์ใด ๆ ที่กล่าวถึงในที่นี้และข้อมูลหรือข้อมูลที่ระบุไว้, หรือว่าผลิตภัณฑ์ดังกล่าว, ข้อมูลหรือข้อมูลอาจถูกนําไปใช้โดยไม่ละเมิดสิทธิ์ในทรัพย์สินทางปัญญาของบุคคลที่สาม. เราขอสงวนสิทธิ์ในการเปลี่ยนแปลงใด ๆ ตามความก้าวหน้าทางเทคโนโลยีหรือการพัฒนาต่อไป.

Functions and uses of dispersants:

Dispersion: Dispersants can disperse solid particles or liquids into liquid media and prevent them from reaggregating. Through the action of surfactants, they encapsulate particles or droplets in micellar structures, making them dispersed evenly, thus forming stable suspensions or emulsions and preventing precipitation and sedimentation.

Preventing precipitation and aggregation: Dispersants can effectively prevent particles or powders from precipitating or aggregating in liquids by increasing their surface activity. They can improve the color development of slurries, making gloss and chromaticity greatly improved, thereby improving the appearance and reliability of applied products.

Stabilization: Dispersants can provide higher dispersion stability and prevent particles from reaggregating to form agglomerates. They reduce the interaction force between particles and hinder the aggregation of particles, thereby maintaining the uniformity and stability of the suspension.

Improving fluidity: Dispersants can improve the flow properties of fluids. When solid particles or droplets are evenly dispersed, they can reduce the viscosity and viscosity of the fluid and improve the flow properties of the fluid.

Thickening: Some dispersants have a thickening effect, forming a colloid or gel structure in the liquid, increasing the viscosity and viscosity of the liquid. This is very useful in some applications, such as seasonings, coatings and adhesives. Adjusting properties: Dispersants can adjust the properties of suspensions or emulsions, such as pH, temperature stability, conductivity, ฯลฯ. They can improve product quality, process performance and use effects.

สารกระจายตัว

TWide range of applications: สารช่วยกระจายตัวใช้กันอย่างแพร่หลายในหลายสาขา, including inks, paints, เคลือบ, การพิมพ์และย้อมสีสิ่งทอ, หมึกอิงค์เจ็ท, pulp and paper, electronic materials, สารกําจัดศัตรูพืช, nanomaterials and other chemical fields. Dispersants have an important impact on the efficiency of the production process and product quality.

ควรสังเกตว่าแม้ว่าสารช่วยกระจายตัวจะมีหน้าที่และการใช้งานหลายอย่าง, it is still necessary to control the amount used and choose the appropriate type of dispersant when using them. การใช้อย่างไม่เหมาะสมอาจก่อให้เกิดอันตรายต่อสุขภาพของมนุษย์และสิ่งแวดล้อม. นอกจากนี้, when using dispersants, ควรปฏิบัติตามขั้นตอนและมาตรฐานการปฏิบัติงานด้านความปลอดภัยที่เกี่ยวข้องอย่างเคร่งครัดเพื่อความปลอดภัยในการผลิตและการใช้งาน.

Q: When do you arrange production?

A: If we have stock, we usually arrange production immediately after receiving your payment. Otherwise, please confirm the delivery time with us.

Q: What payment methods do you accept?

A: T/T, Paypal and Alibaba Trade Assurance. For payment amount less than 400 USD, we only accept Paypal and Western Union and Alibaba Trade Assurance.

Q: Which logistics agent do you usually cooperate with?

A: We cooperate with EMS, TNT, UPS, FEDEX and other logistics agents. Your own freight forwarder can be assigned to you.

Q: What is the calculation formula for the amount of water-based dispersant added?

A: จํานวนเงินเพิ่มเติม (กิโลกรัม) = (total amount of pigment + total amount of filler) x (1-solid content) + solid content.

สารช่วยกระจายตัวทั้งหมดของเราบรรจุในถังพลาสติกส่งออก.

ข้อกําหนดบรรจุภัณฑ์ถังพลาสติกหลักคือ: 25กิโลกรัม, 125กิโลกรัม, 200กิโลกรัม, 1000กิโลกรัม.

ข้อมูลจําเพาะบรรจุภัณฑ์สารกระจายตัว

นอกจากนี้เรายังยอมรับสารช่วยกระจายตัวที่กําหนดเองและผลิตภัณฑ์อื่น ๆ. ยินดีต้อนรับสู่ติดต่อเรา!

Houhuan เคมี

Houhuan เคมี

วีแชท

สแกน QR Code ด้วย wechat