Core problems solved by dispersants in the electronics industry and their specific applications.Dispersants solve several key problems in the electronics industry by optimizing material dispersibility, improving process stability and product performance. The following are their core functions and typical application scenarios:

一、Preparation of electronic ceramic pastes

Problem: Ceramic powders (such as aluminum oxide, zinc oxide, etc.) are prone to agglomeration due to their high specific surface area, resulting in uneven paste viscosity and poor fluidity, which affects coating accuracy.

Solution:

Dispersants stabilize particle dispersion through electrostatic repulsion and steric hindrance effects, improve paste solid content and leveling properties (such as zinc oxide varistor paste).

Reduce secondary flocculation during coating to ensure uniformity and reliability of electronic components (such as varistors, capacitors).

electronics industry

二、Conductive pastes and inks

Problem: Conductive particles (such as silver powder, graphite) are prone to sedimentation in pastes, resulting in unstable conductivity.

Solution:

Graphite powder dispersants ensure uniform distribution of nano-scale graphite particles, improve conductivity and coating uniformity of conductive inks.

Polymer dispersants (such as polyacrylic acid) form steric hindrance to prevent metal particles from agglomerating and optimize the line accuracy of printed circuit boards (PCBs)[4].

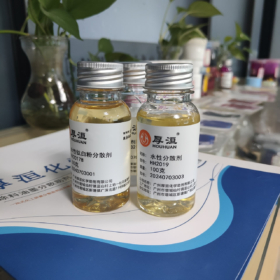

Houhuan Chemical

Houhuan Chemical

WeChat

Scan the QR Code with wechat